Aqueous intaglio inks are quietly shaking up graphic printing because they stick to plastic films and sheets like fast-drying glue. Because the blend is mostly plain water instead of heavy solvent, presses turn jobs around faster, save money, and dodge messy, toxic clean-up. In this post well show what these inks can do, rate their effect on the planet, and prove they keep up with todays lightning-quick press schedule.

The main selling point for aqueous intaglio ink is how gentle it is on Earth. Older solvent blends puffed clouds of volatile organic compounds, or VOCs, into the air; water-based formulas leak almost nothing because their main thinner is just H2O. That steep drop in emissions suits brands and buyers chasing a smaller carbon footprint on every run. By switching to water-based ink, print shops stay ahead of tightening rules and earn trust from eco-minded customers.

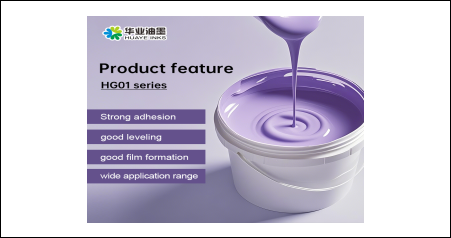

Picture-Perfect Prints

When water-based intaglio ink rolls out, each image sparkles the instant the sheet lands in the catch tray. Those bright colors and fine lines grab onto PE, PP, and a handful of other plastics without melting or blurring. Because the bond is so strong, the finished package looks new for years. Fast drying lets the next step begin long before anyone worries about smudges, giving press crews a helpful speed boost.

Ready for Anything

Since that same ink works on labels, bags, or giveaway cards, brands can chase several markets at once. Snacks, lotions, pills-you name it, the run looks the same whether the product is sweet, scented, or medicinal. Such broad reach lets one print shop fill many shelves while quality stays top tier. Press techs can tweak the formula for extra scratch resistance or a glossy shine, opening even more doors.

Smart Bottom Line

Yes, buying a brand-new aqueous-intaglio press stings your wallet far more than fixing the old one. Still, after only two short test runs, the upgrade starts sending money back toward the register. Faster dry times, less spoilage, and tighter trims save a few cents on every single sheet. And those tough, fade-proof prints cut out expensive re-runs that eat up both hours and cash. Run the numbers, and the new press pays for itself long before the paint stops shining.

Compliance with Industry Standards

Today s tougher safety rules and greener laws are no problem for modern aqueous-intaglio inks; they breeze past every test. Some even clear food-safety checks, so labels for snacks and drinks come off the press worry-free. That reassurance protects shoppers and gives brands a bright, responsible image. Using compliant inks helps every company look like a good neighbor in the community.

Industry Trends and Dynamics

The printing field is now pushing hard for greener habits, and water-based intaglio inks sit at the front. Steady little tech tweaks pull richer color, smoother flow, and fresh options out of each drum. Both rule-makers and picky shoppers simply expect makers to stay ahead of the curve. Printers who hop on early snag a clear marketing boost-proof they care for both the planet and profit.Using water-based intaglio inks can lift plastic printing from dull to brilliant almost overnight. The formulas mix an earth-friendly spirit with sharp lines, broad utility, and a wallet-friendly price while still passing industry tests. Companies that make the swap today quiet their noisy presses and steer the whole trade toward a cleaner, brighter tomorrow.