No.2 Jieqing Road ,Shazai industrial Park, Minzhong Zhongshan City, Guangdong Province

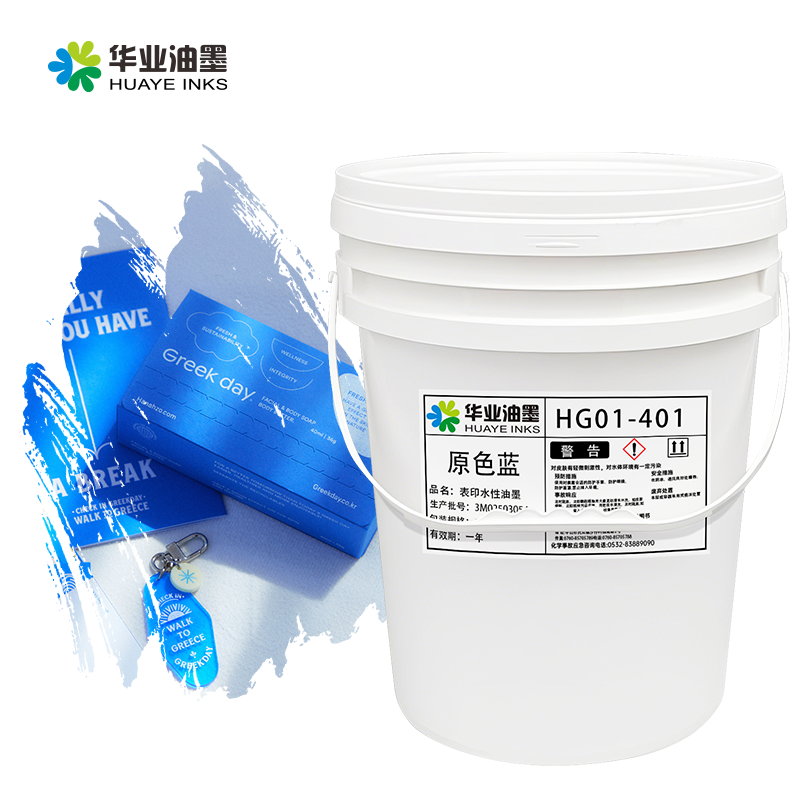

Aqueous intaglio printing ink for plastic bags is a crucial component in the production of printed plastic bags, which are widely used for packaging consumer goods, groceries, and industrial products. Printing on plastic bags requires inks that can meet the specific demands of this application, ensuring both the aesthetic and functional aspects of the packaging. These inks are formulated to adhere well to different types of plastic bag materials, such as polyethylene (PE) and polypropylene (PP). The binders in the ink are designed to create a strong bond with the plastic surface, preventing the printed designs from rubbing off or smudging during the bag - making process, filling, and handling. The pigments used in aqueous intaglio printing ink for plastic bags are carefully selected for their high color strength and good dispersion properties, enabling the reproduction of vivid and clear colors, as well as detailed text and graphics. The drying characteristics of these inks are optimized for the fast - paced production environment of plastic bag manufacturing. In high - volume production lines, the ink needs to dry rapidly to allow for continuous printing without delays. Specialized drying technologies, such as hot air drying or infrared drying, are employed to accelerate the evaporation of water in the ink, ensuring that the printed bags can be processed quickly and efficiently. Aqueous intaglio printing ink for plastic bags also offers good resistance to various environmental factors. It can withstand exposure to moisture, abrasion, and mild chemicals that the plastic bags may encounter during their use. This resistance helps to maintain the integrity of the printed images, ensuring that the brand information and product details remain legible and attractive throughout the lifespan of the plastic bag. With the growing awareness of environmental protection, aqueous intaglio printing ink for plastic bags, which has lower volatile organic compound (VOC) emissions compared to traditional solvent - based inks, is becoming more popular. It provides a more sustainable option for printing on plastic bags, meeting the increasing demand for eco - friendly packaging solutions in the market.