Substrate Compatibility: How Flexo Ink Bonds to Porous Paperboard

Adhesion Mechanisms on Absorbent Paper Surfaces

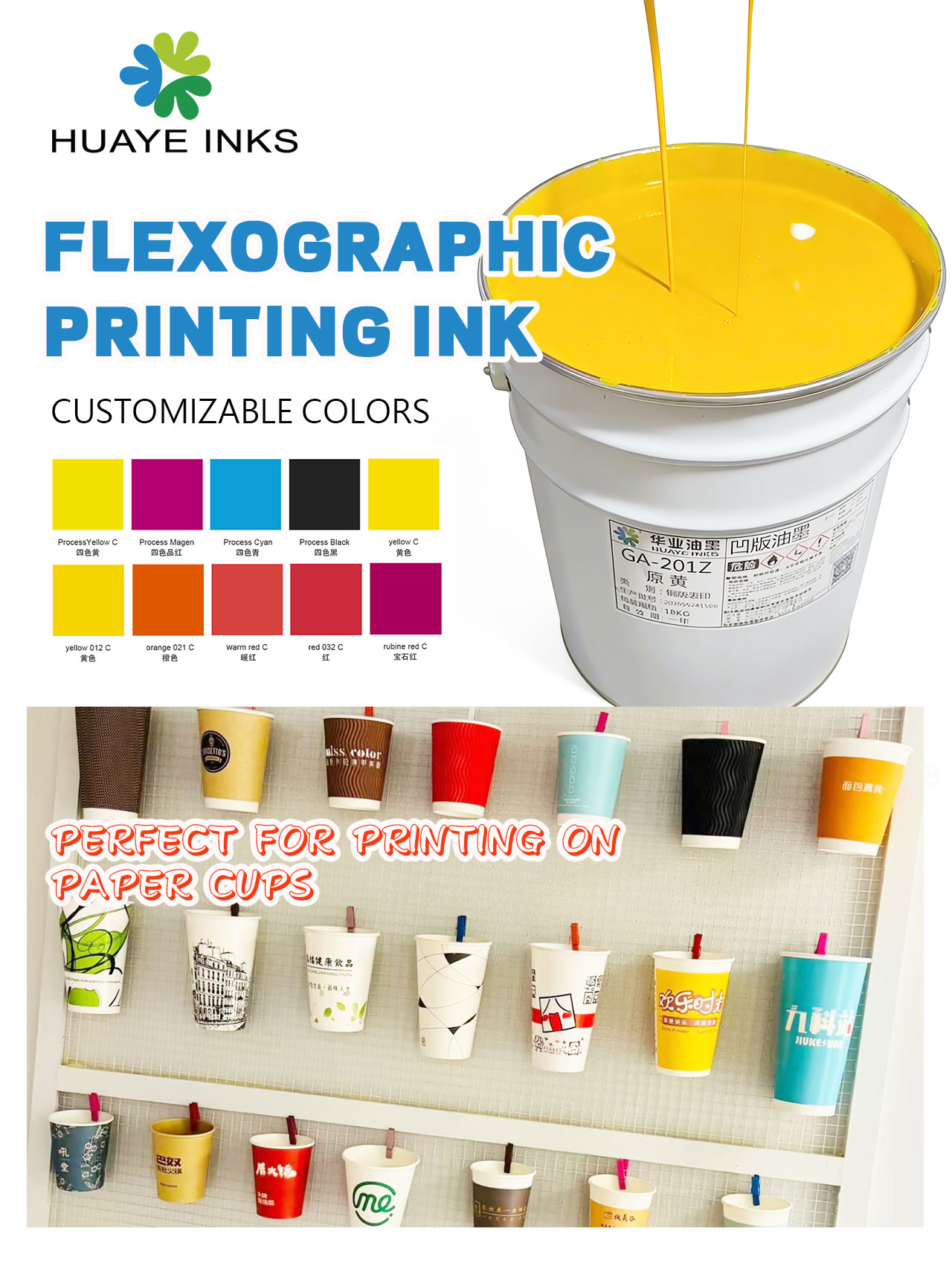

Flexo ink works well with paperboard because it takes advantage of how porous the material naturally is. The ink penetrates quickly into the fibers through what's called capillary action, while the color particles stick to the cellulose chains in the paper. When manufacturers modify acrylic resins, they actually create stronger bonds between the ink and paper surface. These modified resins form special chemical connections with hydroxyl groups on the paper surface, which means the printed image stays put even when things get wet or stressed. This combination of physical and chemical bonding makes sure that printed images stay sharp and don't fade away, something that matters a lot for products like drinks packaging that often sit in damp conditions. Recycled paperboard presents different challenges since it tends to have tiny gaps and uneven surfaces from previous uses. That's where nano-silica comes in handy. These tiny particles fill those gaps without messing up the quality of the print, so brands can still achieve great looking packaging despite using recycled materials.

Viscosity and Rheology Tuning for Consistent Ink Transfer

Getting rheology right matters a lot when it comes to getting ink evenly transferred onto those rough, thirsty paperboards running through presses at breakneck speeds. The sweet spot for viscosity sits somewhere between 0.1 and 0.5 Pa.s at around 10,000 seconds inverse. This range keeps pigments suspended properly while allowing the ink to thin out just enough under pressure, which helps avoid problems like dot gain or feathering issues. When working with pseudoplastic thickeners, they actually lower the viscosity as the press applies shear force, making all the difference for crisp details on surfaces with low surface energy measurements typically found between 32 and 38 mN/m. There's more to it though. Adding pH buffers helps keep acrylic emulsions stable as they get absorbed into the substrate. And don't forget about surfactants either these little helpers adjust the interface tension so we end up with ink films that weigh in at 1.2 to 2.4 grams per square meter without worrying about ink bleeding through or losing opacity. These factors are super important for meeting food packaging standards and keeping materials costs down in production runs.

Food-Safe Compliance: Water-Based Flexo Ink Meets Regulatory Standards

FDA, EFSA, and EU 10/2011 Compliance for Direct Food Contact

Water based flexo inks comply with all major international food contact regulations around the world. These include requirements from the FDA under 21 CFR sections 175.105 and 176.170 regarding indirect contact, plus safety evaluations by EFSA for food grade materials, and the EU's Regulation 10/2011 that sets migration limits specifically for fatty foods. What makes them stand out compared to solvent based options? They simply don't contain those harmful photoinitiators, dangerous heavy metals, or leftover solvents that can migrate into food products. To ensure everything stays within safe limits, manufacturers use specially purified pigments and binders that won't leach over time. There's also extensive testing where samples are exposed to conditions similar to hot beverages at 90 degrees Celsius (or 194 Fahrenheit) and put through accelerated aging processes. Every single component must stay well under the strict 0.01 milligrams per kilogram contamination limit set for applications where ink comes directly next to food items.

Low-Migration Formulations and VOC Reduction in Modern Flexo Ink

Water based flexo inks today incorporate specially designed polymer structures that wrap around pigment particles, cutting down on migration risks by almost 97% compared to older methods. Volatile organic compounds? They're now at less than 1% of what solvent based products contain, which actually meets those strict California Air Resources Board standards as well as global indoor air quality requirements. The formulation swaps out glycol ethers for safer alternatives that still let materials dry really fast, under half a second even on high speed cup production lines. And here's something important for recycling efforts these days the new formulas don't have any halogenated chemicals in them. This means paper products stay recyclable without contaminating the pulp streams during processing, which is becoming increasingly critical as environmental regulations tighten across industries.

Efficient Drying & Curing: Balancing Speed, Quality, and Substrate Integrity

Evaporation-Based Drying for Heat-Sensitive Paper Cups

Water based flexo ink dries through controlled evaporation making it great for those thin walled paper cups that are sensitive to heat. The process works best when temperatures stay between about 40 degrees Celsius and 60 degrees Celsius. At these levels there's no risk of warping the cups, catching them on fire, or losing their insulating properties in single wall designs. Modern systems now use inline moisture sensors to get the drying time just right. This has helped manufacturers boost their production cycles by around 25 to 27 percent according to industry reports. Plus, there are zero VOC emissions from this method anymore. What we end up with are cups that hold their shape well, won't leak, and maintain good thermal characteristics throughout normal usage conditions.

UV/LED Flexo Ink Options for High-Speed, Low-Energy Production

When combining UV curable flexographic inks with LED technology, printers get instant cold set curing that lets presses run at over 300 meters per minute, which is roughly 80% quicker compared to traditional methods. These LED UV systems actually use around 60% less power than those old mercury arc lamps, plus they give off almost no infrared heat. That matters a lot when printing on things like thin paper bowls that would warp under regular heat sources. Another big plus is these systems produce practically zero volatile organic compounds, so there's no need for those bulky post drying ovens taking up space in production lines. The end result? Graphics that resist scratches during shipping and handling, all while cutting down on carbon emissions from operations across the board.

Functional Print Performance: Durability Under Real-World Conditions

Flexo inks designed for advanced applications keep prints looking good throughout the entire life of paper cups and bowls. They handle all sorts of challenges including moisture from cold drinks, heat damage from hot beverages, wear and tear while being stacked and transported, plus constant touching by customers. The way these inks bond with the paper at a microscopic level actually stops them from cracking, flaking off, or getting smeared away, no matter how many times they're rubbed against other packages during shipping. What's really important here is that this kind of tough performance doesn't affect food safety standards. At the molecular level, the ink sticks so well to the surface that there's absolutely no risk of chemicals moving into whatever food touches those printed areas.

FAQ

What is the main advantage of flexo ink bonding with paperboard?

The main advantage is the combination of physical and chemical bonding, which ensures that the printed images remain sharp and do not fade over time, especially in damp conditions.

Why is viscosity important in flexo ink application?

Viscosity is crucial for ensuring ink is evenly transferred to porous paperboards, maintaining pigment suspension, and avoiding issues like dot gain or feathering.

How does water-based flexo ink ensure food safety compliance?

Water-based flexo inks comply with international food safety standards, as they don't contain harmful chemicals like photoinitiators or heavy metals, and they undergo rigorous testing to meet contamination limits.

What benefits do UV/LED flexo ink systems offer?

UV/LED flexo ink systems provide fast curing, reduced power usage, minimal heat emission, and fewer VOCs, making them ideal for high-speed, low-energy production.